Tagco furnace Bogie Hearth furnaces are lined with ceramic fibre modules/blankets on the side wall, roof and door and hearth of the furnace will be provided with combination of high/medium grade aluminium bricks backed-up by insulation bricks to minimize the skin temperature.

Temperature control and atmosphere versatility.

Focus on efficiency and sustainability.

Durability and safety.

years of experience

We have a highly qualified and experienced team of quality control managers who ensure that every phase of production, from design, drawings, and procuring of the raw material to completion and delivery, goes through strict and uncompromising quality control audits. Cautiousness is carefully carried out to ensure all parameters of international quality standards are met.

Tempering furnace is a type of industrial oven used in heat treatment to modify the mechanical properties of metals, particularly steel. Making the metal more suitable for various applications.

Hardening is the process of heat treatment in which steel is kept at a suitable temperature till it gets transformed into austenite and then quenching it rapidly.

An annealing furnace is a specialized industrial furnace used to heat materials, typically metals, to high temperatures and then cool them at a controlled rate.

Gas-fired ovens, commonly used in both residential and industrial settings, offer efficient and precise temperature control for cooking and heating processes.

This design allows for easy loading and unloading of heavy or large workpieces, making it suitable for heat treating processes like annealing, normalizing, hardening, and stress relieving.

Trolley-type ovens are industrial ovens designed for batch processing of materials using removable trolleys or racks. Key features include large capacity, uniform heating, and robust construction.

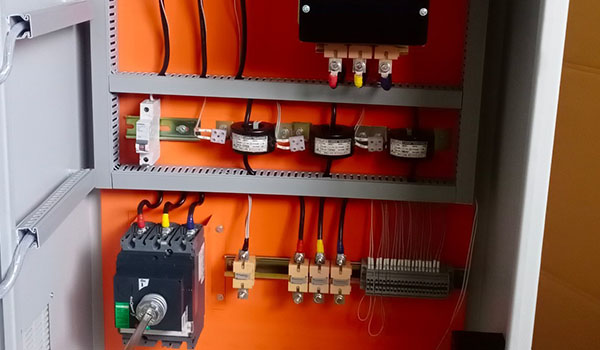

A furnace control panel manages the various components of a furnace to ensure it operates safely and efficiently. It receives signals from the thermostat, activates the draft motor, checks for proper pressure, ignites the gas, and controls the blower motor to distribute warm air.

Our Enginer and Techician under taking of Wiring as per Industial Standard. All Wiring carryout full printed tag with each side.

We are taking full responibility of Furnace and Oven reparing works with qualified Enginers and Technicians.

TAGCO take full responsibility for ensuring proper planning during the initial stage of the project. Our approach includes. - Developing a comprehensive and realistic project plan. - Coordinating with our valued customers to understand their expectations. - Engaging in detailed discussions to refine goals and deliverable. - Submitting a well-structured project schedule for approval We are committed to excellence from the very beginning to ensure a successful and timely project execution.

Design - Thermal Efficiency: Optimize insulation, heat recovery systems, and combustion control. - Material Selection: Refractories for lining, steel casing, heat-resistant components. - Structure Layout: Loading/unloading mechanisms, ventilation, pressure control. - Automation and Control Systems: Sensors, temperature regulation, programmable interfaces. Engineering Calculations - Heat transfer analysis: conduction, convection, radiation. - Structural integrity: stress analysis, expansion joints. - Fluid dynamics for air/gas flow. - Energy consumption and emission models.

- Design according to applicable standards (ASME, ISO, BIS) - Fire suppression systems. - Emergency shutoffs and protective barriers. - Environmental impact: emission controls and filtration systems.

Commissioning and handover are the final stages in a project, ensuring the completed facility is fully functional and ready for operation by the end user. Commissioning involves rigorous testing and verification of all systems, while handover formalizes the transfer of ownership and documentation to the client. These processes are crucial for confirming that the project meets all requirements, operates as intended, and is safe for occupancy.